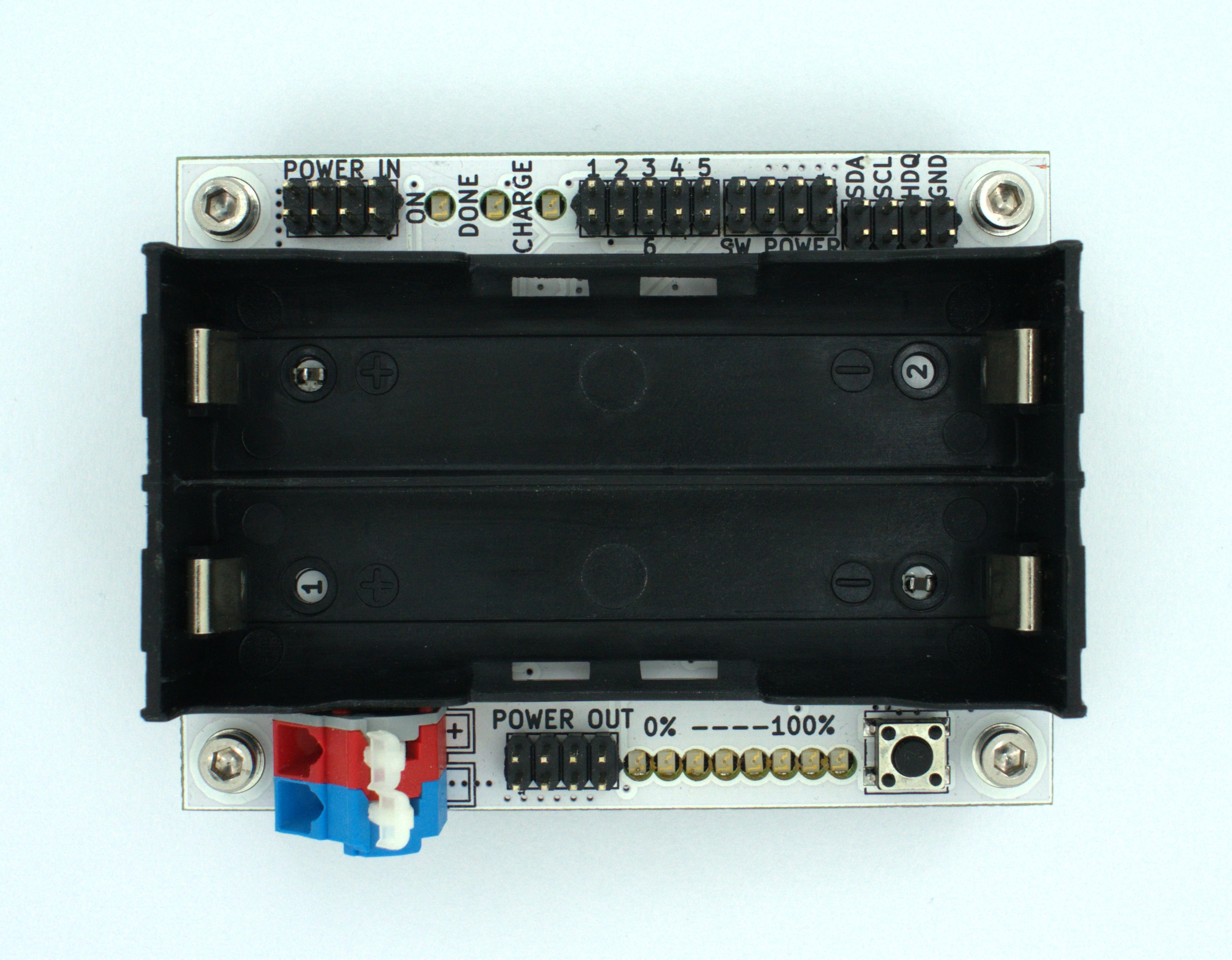

LION2CELL01D - Li-ion dual-cell Battery Management Module

Description

The LION2CELL01D is an integrated battery management solution for 18650 Li-ion batteries. It is designed to manage the charging, balancing, and monitoring of two series-connected Li-ion cells. This module measures the remaining energy, voltage, and temperature of the batteries, and protects against over-voltage and over-draining conditions.

Features

- Charging and Balancing: Supports charging, balancing, and termination with temperature protection.

- Gas-gauging: Temperature-compensated gas-gauging for accurate remaining energy estimation.

- Protection: Over-voltage, over-current protection, but no under-voltage protection (the module operates until battery depletion).

- Communication: Supports I2C and HDQ communication interfaces.

Technical Specifications

- Power Supply: 12 V @ 2 A

- Charging Current: Factory set to approximately 1.3 A

- Battery Holder: 2x 18650

- Interfaces: I2C, HDQ

- Integrated Circuits:

- BQ24103 for charging

- BQ34Z100 for fuel gauging

- Dimensions: 80.77 x 60.45 x 16 mm

Connection

| Pin |

Signal |

Description |

| 1 |

PG |

Power Good |

| 2 |

STAT2 |

Status Indicator |

| 3 |

GND |

Ground |

| 4 |

CE |

Chip Enable |

| 5 |

STAT1 |

Status Indicator |

| 6 |

CMODE |

Configuration Mode |

Construction

The module is constructed with three main functional blocks:

1. Charging Circuitry: Manages the charging process of the two series-connected Li-ion cells.

2. Measurement Circuitry: Measures the voltage, current, and temperature of the cells.

3. Balancing and Protection Circuitry: Ensures cell voltage balancing and provides protection against over-voltage.

Important Considerations

- Regular charging is required (at least once every six months) to maintain the batteries within operational voltage ranges.

- Specific resistor values and settings are used for the voltage measurement, ensuring accurate readings without exceeding voltage limits.

- The module is equipped with a balancing circuit that discharges one of the cells to match the voltage of the other, with a discharge current around 10 mA.

Setup and Configuration

- Installation:

- Check the PCB for proper soldering.

- Insert the batteries in the designated order: position 1 first, followed by position 2.

-

Verify the operation of the charging function by connecting a 12V adapter.

-

Software:

- Use

setguage2cell.py to upload parameters to the energy measurement circuit.

- Parameters are tailored for Panasonic NCR18650B or INR18650MJ1 cells; adjustments are needed for other types.

- Conduct at least one charge/discharge cycle for accurate energy measurements.